A chef's guide to sharpening stone grit

Whether you’re a professional chef or a home cook, it’s a universal truth that the usage of sharpening stones effectively can greatly enhance your knife care routine. It improves cutting efficiency and extends the life of your knives, basically making them easier, safer and more enjoyable to use.

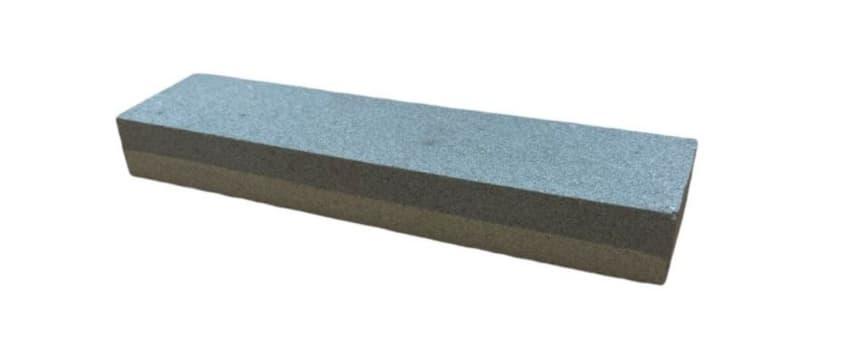

That makes sharpening stones and whetstones hugely important in any food preparation environment – they help correct imperfections, refine edges, and polish blades. Some chefs and butchers understandably prefer electric sharpeners or honing rods, while others favour sharpening stones for the precise control they offer over the sharpening process.

This is where sharpening stone grits come in.

What is sharpening stone grit?

Sharpening stones come in various “grit” sizes, each one of which serves a specific purpose in the sharpening process. The grit size is measured by the number of abrasive particles per square inch, and affects the stone’s ability to remove metal and the smoothness of the finished edge. Here’s a brief overview of the most common grit sizes:

- Coarse grit stones (200-600 grit): These are used for heavy-duty tasks such as repairing damaged edges or reshaping blades. They remove a substantial amount of metal quickly, but they can leave a rough surface that requires additional refinement.

- Medium grit stones (800-2000 grit): These are used for general sharpening and refining the edge after using a coarse stone. They prepare the blade for finer finishing, and they’re suitable for most kitchen tasks.

How do I choose the right stone grit?

There are several key factors which you’ll need to consider to ensure you pick the right sharpening stone grit. If your knife has a dull or damaged edge, it’s a good idea to start with a coarse grit stone to reshape the blade. For regular maintenance, a medium grit stone is generally sufficient. The type of knife and its intended use also influence your choice. For instance, a chef’s knife might benefit from a finer grit to achieve a sharper edge, while a paring knife may only need a medium grit for routine touch-ups.

Plus, it’s a good idea to bear in mind how frequently you use your knives, and the type of cutting tasks you perform. Frequent use or precision tasks may require finer grits, while medium grits might be just fine for less frequent or heavy-duty use.

How to prepare your stones, and properly sharpen your knives

As you’d expect, proper preparation of your sharpening stone is always going to be the cornerstone of effective sharpening. Most sharpening stones, particularly water stones, need to be soaked in water before use. This soaking keeps the stone’s surface wet and prevents it from clogging with metal filings. Typically, water stones should be soaked for about 10 to 15 minutes, but it’s best to follow the manufacturer’s instructions.

For oil stones, you’ll instead need to lubricate them with honing oil. This oil helps to remove metal particles and keeps the stone’s surface clear. And of course, you’ll need to ensure that you’ve set up your sharpening station on a stable, non-slip surface with good lighting. Placing the stone on a non-slip mat or towel helps keep it steady during use.

OK, so once you’ve got everything set up, it’s time to move on to the sharpening itself. Effective sharpening involves mastering specific techniques to achieve a sharp, functional edge. Begin with a coarse grit stone if the blade is very dull or damaged. Maintain a consistent angle, usually between 15 to 20 degrees, and use even strokes to ensure an even edge. After major sharpening, move to a medium grit stone to refine the edge, and finish with a fine grit stone for polishing.

Make sure to avoid some of the most common mistakes – for example, don’t apply too much pressure, as this can damage the stone and the blade, and don’t vary the angle, which can lead to uneven sharpening. It’s worth us reiterating – proper lubrication is absolutely vital to prevent clogging and ensure a smooth sharpening process.

Maintaining and caring for sharpening stones

Maintaining your sharpening stones is key to their longevity and performance. After each use, clean the stones thoroughly to remove metal filings and debris. From there, if you’re using water stones, make sure to rinse them under running water and let them air dry before storing. For oil stones on the other hand, wipe them with a cloth and a bit of oil. In both cases, you’ll want to store stones in a dry place to prevent damage.

To prolong the life of your sharpening stones, make sure to regularly flatten them with a flattening plate to maintain an even surface. Try to avoid dropping or knocking the stones, as this can cause chipping or cracking. Following the manufacturer’s instructions and using the stones properly will help ensure they remain effective tools for sharpening your knives.

And of course, if you’re looking for the very best tools for sharpening your knives, we have an excellent range of sharpening stones and whetstones for sale right here at Butchers Equipment Warehouse, encompassing a variety of grits – so you’ll always have ready access to the tools you need to get the job done. If you ever need any help or advice on choosing the right sharpening stone for you, feel free to give us a call on 01254 427 761, and we’ll always be happy to help!